your current location:Home>Surface roughness requirements for cylinder rods

Surface roughness requirements for cylinder rods

Published: 201905-11 Clicks: times

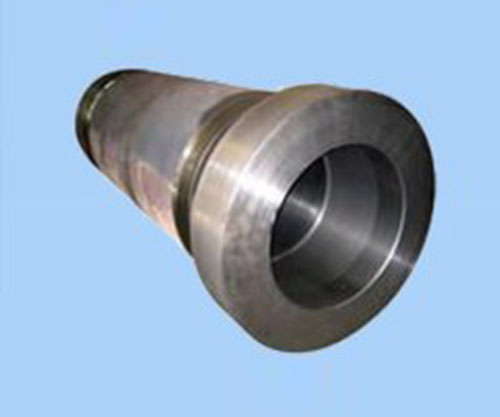

The piston rod is a connecting member that supports the work of the piston, and is mostly used in the motion executing parts of the cylinder and the cylinder (compressed air). Compared to other moving parts, the piston rod is a moving part with high movement and high technical requirements.

Piston rod is composed of cylinder, piston rod or cylinder rod, piston and end cap. Its surface roughness is required to reach Ra0.4-0.8um and coaxial. The requirements for degree and wear resistance are very strict. In addition, the processing of slender shafts like cylinder rods has always been a major problem for the staff. Therefore, the technical requirements of the piston rod in processing are an important feature. It can be said that the quality of the processing technology directly affects the quality of the product and the length of use.

Cylinder piston rod is an important part of the cylinder. It is usually made of 45# steel as a solid rod or hollow tube. The piston rod is subject to abrasive scouring during use and is prone to wear (a basic type of component failure). The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. At present, the traditional domestic process is hard chrome plating (a traditional surface plating technology) (coating thickness 0.03~0.05mm) and polished, and the surface roughness (cū cāo) degree Ra is 0.1~0.2μm. The plating solution is based on chromic acid and uses sulfur (chemical symbol: S) acid as a catalyst. The process advantages are: stable plating solution (interpretation: stable stability; no change), easy operation and control, and high quality of surface chrome plating. Entity to the oil rod bright, high hardness (Hardness), excellent wear resistance and other advantages

You may also be interested in this

Related Reading