your current location:Home>Heat treatment of cylinder rod

Heat treatment of cylinder rod

Published: 201905-11 Clicks: times

【Key words】 Cylinder piston rod Plating crack Cause analysis

1 Introduction

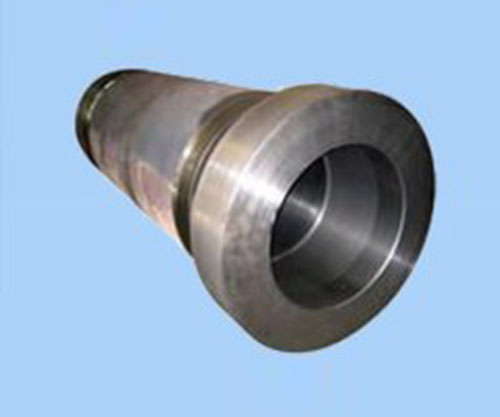

The hydraulic cylinder is an important actuator in the hydraulic system of the construction machinery. It is used to perform reciprocating motion and drive the construction machinery to perform various functions. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The piston rod is a key force-transmitting part with high technical requirements for connecting the piston and the working part in the hydraulic cylinder. It needs to bear large tensile stress during the working process. Therefore, the piston rod must have sufficient strength, rigidity and toughness, and at the same time It is easily eroded by abrasive particles and must have high wear resistance. The long cylinder piston rod is made of 45 steel, and its processing route is: forging material (rolled material) & mdash; blanking & mdash; quenching & tempering & mdash; straightening & mdash; machining & mdash; surface quenching, tempering & mdash; straightening & mdash; Head welding & mdash; machining & mdash; grinding & mdash; stress relief annealing - polishing & mdash; hard chrome & mdash; polishing & mdash; cleaning & mdash; assembly. The heat treatment of the piston rod is the key process to ensure the internal quality and mechanical properties of the piston rod. The quality of the heat treatment is directly related to the life and reliability of the entire hydraulic system. If the heat treatment is improper, the piston rod will be broken early during use, and the other will be damaged. Parts, in severe cases, may cause damage to the entire equipment and casualties.

2 quenching and tempering treatment

The purpose of quenching and tempering treatment (chǔ lǐ) is to make the piston rod have comprehensive mechanical properties with good matching of strength, hardness, plasticity and toughness. The internal structure is uniform (jūn yú n) fine tempered sorbite for subsequent surface quenching (quenching) Prepare for organization. The long cylinder piston rod has a length of 3800-4200 and a diameter of Φ 90-Φ 110mm. Therefore, the heating equipment adopts a 150KW well resistance furnace or a 600KW suspension continuous resistance heating furnace, and the temperature is controlled by two zones. Heat treatment process parameters: In the well type furnace, 4 furnaces are suspended, the quenching heating temperature is 830 ± 10 °C, after 160 minutes of heat preservation, the furnace is quenched twice, each time quenching 2, using circulating cooling water to cool, quenching and cooling Swing to ensure maximum cooling evenly, cooling to about 100 ° C (the rod steam but not foaming) effluent into the well tempering furnace temper. Then 4 sets of 550± were used once; heated at 10 °C, tempered for 190 minutes, and tempered and then water cooled. After the above process quenching and tempering treatment, the performance is unstable (interpretation: stable stability; no change), the hardness fluctuates between 210-255HBS, and the hardness of the upper, middle and lower piston rods of the same piston rod also differ greatly. And sometimes there are individual furnace hardness failure or low strength, need to be repaired. The quenching deformation is relatively large, which increases the difficulty of subsequent alignment and machining. Due to the poor hardenability of 45 steel, the metallographic observation of its internal structure is not a single uniform tempered sorbite, but a large piece of free iron body in its core, and there are mesh iron bodies and Wei's organization in individual parts. .

In order to solve the above problems, we use quenching continuation heat treatment quenching furnace for quenching heating, each mounting 2, after heating and heat preservation, the furnace is automatically quenched, and each section is shot to ensure uniform heating. Considering that the Ac3 temperature of 45 steel is 770-780 °C, in order to refine the grain as much as possible and reduce the deformation, we use 790± 10 °C sub-temperature quenching process to refine the austenite grains and obtain fine and uniform after quenching. Lath martensite to enhance the toughness of the piston rod. In order to further reduce the deformation and improve the quenching liquid cooling uniformity, we add 5%-10% quenching additive in tap water. When quenching, the circulating water pump is also used to force the coolant to circulate and cool. The tempering is still 550± 10 °C heating, the beat is the same as the quenching beat, and the water is cooled after tempering to suppress the second type of temper brittleness. After the above process is improved, the internal structure is uniform fine tempered sorbite, and the bulk or reticular ferrite and Wei's structure are removed, and the hardness is uniform and stable.

3 surface hardening

In the working process of the piston rod (guò ché ng), the movement is frequent and the force is complicated. Therefore, in addition to the requirement of good comprehensive mechanical properties to prevent deformation and fracture, the surface is required to have high wear resistance and the surface hardness is required to be achieved. 58-62HRC, high frequency quenching is often used in the process of production. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The quenching equipment adopts a semi-automatic continuous quenching heating furnace, and the piston rod is transported by the feeding machine to the conveyor belt of the quenching furnace, and is heated and quenched by feeding the belt horizontally and uniformly into the induction coil. The key to surface quenching is the choice of induction coil fabrication and quenching process parameters. The induction coil is made of 10*8mm rectangular copper tube, and is designed as a double-layer structure placed side by side. The front and rear rings are separated by a certain distance. The front ring does not make a water spray hole, and the front ring is used for preheating. The water hole with a hole diameter of 0.9mm in the rear circle is evenly distributed along the circumference, and the water spray angle is designed to be 36 degrees; the inner diameter of the induction ring is 4-5 mm larger than the outer diameter of the piston rod. The quenching heating anode voltage PV is 11-12KV, the anode current PA is 1.9-2.2A, and the gate current GA is 0.38-0.40A. The piston rod moving speed is controlled by adjusting the rotation speed of the piston rod feeding frame to heat the piston rod surface to After 890-910 °C, the water spray is cooled. The quenching liquid is made by using special quenching liquid and dilute with 50-60% water. The water spray pressure is maintained at about 0.1 MPa. By controlling the water spray cooling time, the temperature of the product after water cooling is controlled, and the residual heat is used for tempering. After testing, the depth of the hardened layer is 2-3 mm, the surface layer is tempered martensite, the core structure is tempered sorbite, the surface hardness is 58-60HRC, and the core hardness is 210-230HBS.

4 stress annealing (annealing)

Since surface quenching is tempering by using the product's own residual heat, the tempering temperature is gradually reduced (step by step), there is no complete tempering and heat preservation process, the tempering time is short, the stress elimination is incomplete, and some products exist. Large residual stress. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. In the subsequent grinding process, if the internal stress of the grinding is superimposed on the residual internal stress of the surface quenching, when the stress exceeds the tensile strength of the material, stress cracks may occur on the surface of the piston rod if the stress does not exceed the tensile strength of the material. It exists in the form of residual stress in the product, causing cracking of the coating due to redistribution of stress during subsequent chrome plating or use, causing cracks in the chrome plating layer. Therefore, the piston rod must be annealing before chrome plating to eliminate the internal stress generated by grinding and surface treatment. The stress relief annealing heating temperature is 200-230 ° C, and after 190 min of heat preservation, the furnace is cooled to 160 ° C to be air-cooled.

5 Conclusion

After the quenching and tempering treatment, the piston rod obtains good comprehensive mechanical properties and is ready for the subsequent surface treatment. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. The hollow piston rod refers to a hollow piston rod having an annular cross section. The purpose of surface hardening is to obtain a high surface hardness to support the surface chrome plating layer, thereby improving the wear resistance and corrosion resistance of the piston rod. The stress relief annealing is arranged before the electroplating after the grinding process to completely eliminate the residual stress inside the piston rod, improve the plating quality and the product qualification rate, and improve the service life of the piston rod.

You may also be interested in this

Related Reading