your current location:Home>The importance of polishing and assembly for the piston rod

The importance of polishing and assembly for the piston rod

Published: 201905-11 Clicks: times

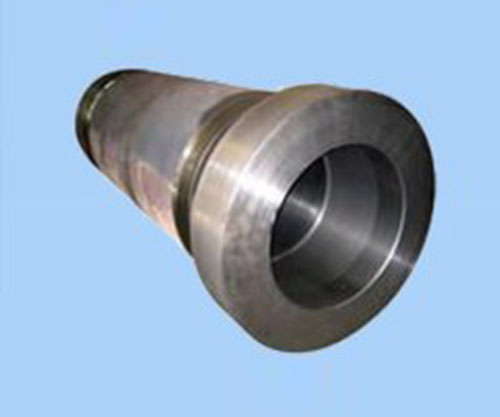

I don't know how much you know about the Piston rod, but if you want to use the piston rod to do the work, then we should look at the method to install the piston rod. And polishing will be better. In the course of this assignment (guò ché ng), what should we pay attention to? Interested friends may wish to take a look.

1. Combination installation work of piston rods

If you want to assemble a piston rod, then naturally we should know what his specific operation is. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. If there is a need, then we should also rotate the piston. But in this process we should also pay attention to prevent the occurrence of bias and bite (Condition). In our fit for the installation of the piston rod, we should also ensure that he does not have loose conditions. In addition, we should also look at how his order is. If there is any problem with the direction and order (Emerson), then the impact will be relatively large.

2, the polishing problem of the piston rod (Emerson)

If you want to polish the piston rod, then naturally we should also ensure that the quality of the piston rod is not a problem, so we can judge by our inspection (tōng guò). The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. When we are inspecting the piston rod, we should also look at the pressure and feed of the bridge crane. After that, we should also polish according to the regulations (guī dìng), of course, for the quality The requirements are also very critical. In addition to this child, we should also look at how his depth and angle change in the piston rod. Generally speaking, his Mo grinding amount is also relatively large, so pay attention to the situation of corrosion (Condition). appear.

After saying so much about the piston rod, we should also know what method to use to operate the piston rod. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. Of course, we also look forward to the opportunity to communicate and cooperate with you. We are specialized in the work of piston rods. You can rest assured.

You may also be interested in this

Related Reading