your current location:Home>How to improve the corrosion resistance of the piston rod su

How to improve the corrosion resistance of the piston rod su

Published: 201905-11 Clicks: times

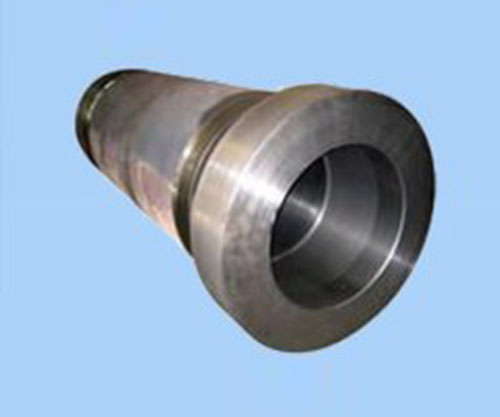

Piston rods are currently widely used in most of the joint parts of a product. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. However, due to the harsh environment (liè) (nasty) of some mechanical applications, there is a higher requirement for the corrosion resistance of the piston rod. So how should we improve the corrosion resistance of the piston rod surface? Improve the corrosion resistance of the piston rod surface: 1. Rolling processing: through (tōng guò) rolling forming, forming a cold hardening layer on the rolling surface Maximizes the elastic and plastic deformation of the grinding contact surface and delays the generation or expansion of fatigue cracks, thereby improving the surface corrosion resistance. 2. Chrome plated (Chromium): The piston rod is chrome-plated to have a hard, smooth, corrosion-resistant surface. Therefore, if you want to improve the corrosion resistance of the piston rod surface, you need to pass chrome plating. After chrome plating, the hardness of the piston rod can be as high as HV1100, and the coating is smooth and uniform in thickness (jūn yú n), and the dispersion ability is strong, which can greatly improve it in some aspects. 3, quenching and tempering: quenching and tempering is to quench and temper the piston rod (chǔ lǐ), after quenching and tempering treatment, can effectively improve the material (strength) of the material, which helps to close the surface micro crack. It hinders the expansion of erosion and thus improves the surface corrosion resistance. However, not all piston rods need to be tempered, so the quenching and tempering process should be judged according to the actual situation (Condition) and materials. The content of the website described above is a way to improve the corrosion resistance of the piston rod surface. The better the corrosion resistance of the piston rod surface, the easier it is for the piston rod to be eroded and the longer the life of the piston.

You may also be interested in this

Related Reading