your current location:Home>Why is our piston rod always bad, what caused it?

Why is our piston rod always bad, what caused it?

Published: 201905-11 Clicks: times

1, How to judge the replacement of the piston rod

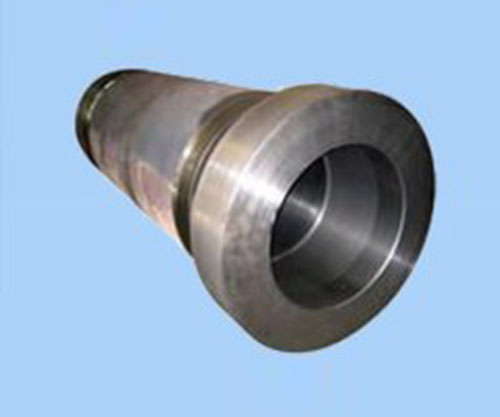

When we are plating the piston rod, if we want to guarantee the performance of his plating, we have to control his temperature, so that our plating work can Successful completion. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. If he has a slight scratch in the piston rod, we can adjust it manually (tōng guò). If he has wear (a basic type of component failure), then we can weld it. The place is adjusted. After welding, we have to look at his size so as to prevent his hardness and roughness (cū cāo). There are other reasons that can cause damage to the piston rod. At this time, we can repair it by welding.

2, Piston (piston) rod is always bad cause (cause)

If we are installing the cylinder, his concentricity does not meet the requirements. This may be because he has a lot of liquid in the gas, which will cause our piston rod to be impacted. In the future, he will get stuck and there will be a break (Condition). When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. When we process the piston rod, if the bottom angle of the thread is relatively small, it is easy for him to appear to be biased, so that it will not be damaged? In addition, he may also be because the design of the cylinder does not meet the requirements. The wrong position in the buffer will also lead to a series of problems (Emerson).

When we use the piston rod, there are actually many reasons that cause him to be damaged, but we still need to analyze the specific problem. The hollow piston rod refers to a hollow piston rod having an annular cross section. If you have any questions that you can't solve, you can ask us and hope that our introduction will help you.

You may also be interested in this

Related Reading