your current location:Home>Excellent performance of stainless steel piston rod after ro

Excellent performance of stainless steel piston rod after ro

Published: 201905-11 Clicks: times

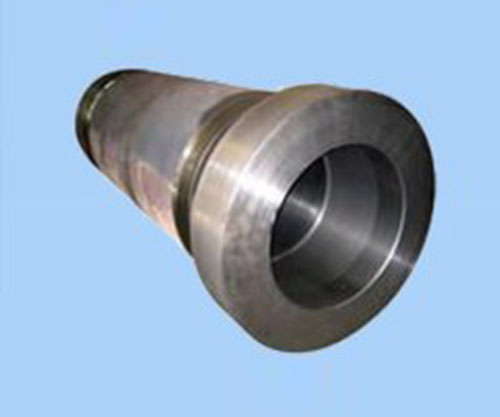

and prevent stainless steel (stainless acid-resistant steel) piston (Piston) rod erosion, to maximize the ability of stainless steel piston rods to resist corrosion and corrosion on the surface, mainly to crack The fatigue is delayed, which are the advantages of stainless steel piston rods (tǐ xià n), and can improve the degree of fatigue resistance. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight.

After rolling the stainless steel (stainless acid-resistant steel) piston rod, a cold hardened layer is formed on the surface after rolling, which is reduced due to grinding. Contact with the surface, and effectively reduce the plastic and elastic deformation, the most effective to improve the wear resistance of the entire surface of the stainless steel piston rod. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements.

can also avoid the burn of the stainless steel piston rod caused by grinding, after the rolling treatment (chǔ lǐ), the roughness of the entire surface will be reduced, Appropriate improvement in properties can also reduce the friction of the seal ring and the seal, but the life of the cylinder is significantly improved.

Stainless steel (stainless acid-resistant steel) piston (piston) rod rolling process, is a kind of efficient (referring to high efficiency), and very good quality process measures (pointer to solve the problem) Method) If the piston rod with a diameter of 16 mm is used as a case analysis (Analyse), after the rolling treatment (chǔ lǐ), the piston rod can undergo a very large change in the surface roughness (cū cāo). .

First of all, the life of the cylinder is used, followed by the strength of fatigue resistance, and the hardness of the surface, etc., can be better improved, and the entire process is improved by at least 15 in efficiency. Times, after the above introduction, is it enough to prove that the rolling technology is very efficient. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts.

You may also be interested in this

Related Reading