your current location:Home>Introduction of stainless steel piston rod

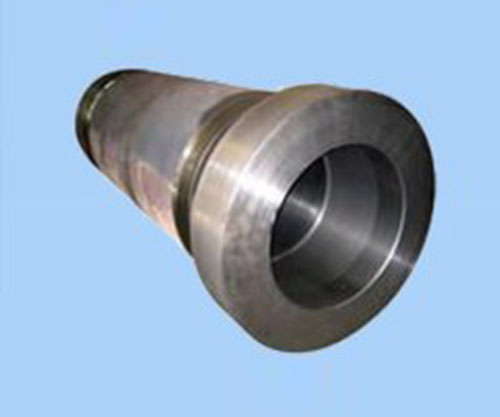

Introduction of stainless steel piston rod

Published: 201905-11 Clicks: times

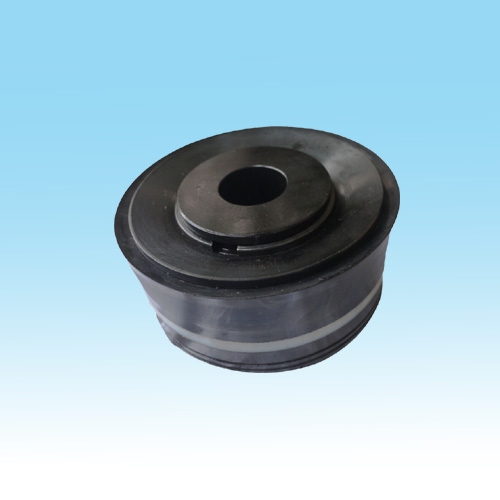

Stainless steel (stainless steel) Piston rods are mainly used for hydraulic pneumatics, construction machinery (an important part of the equipment industry), and piston rods for automobile manufacturing. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The hollow piston rod refers to a hollow piston rod having an annular cross section. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. The piston rod is processed by rolling, and the residual stress on the surface layer is left to help the surface of the surface crack, which hinders the expansion of the erosion. Thereby, the surface is resistant to corrosion and corrosion, and the occurrence or expansion of fatigue cracks can be delayed, thereby improving the fatigue strength of the cylinder rod. By rolling (tōng guò), the rolling surface forms a cold hardening layer, which minimizes the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface while avoiding A burn caused by grinding. After rolling, the reduction of the surface roughness (cū cāo) value can improve the compounding property. At the same time, the friction damage to the seal ring or the seal during the movement of the cylinder rod piston is reduced, and the life of the overall use of the cylinder is improved. The rolling process is a high-efficiency (high-performance) high-quality process (point-to-problem solution), now with a diameter of 160mm mirror doctor rolling head (45 steel seamless steel pipe) as an example (zhè ;ng míng) rolling effect. After rolling, the surface roughness of the cylinder rod is reduced from Ra3.2~6.3um before the rolling to Ra0.4~0.8um, the surface hardness of the cylinder rod is increased by about 30%, and the fatigue strength of the cylinder rod surface is increased by 25%. . The service life of the cylinder is increased by 2 to 3 times, and the rolling process is improved by about 15 times compared with the efficiency of the grinding process. The above data (data) shows that the rolling process is highly efficient and can greatly improve the surface quality of the cylinder rod.

You may also be interested in this

Related Reading