your current location:Home>Piston rod processing process table and process analysis

Piston rod processing process table and process analysis

Published: 201905-11 Clicks: times

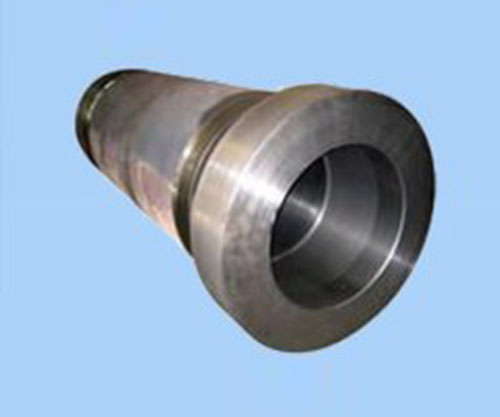

Piston rod drawing cylinder piston rod processing process card and process analysis (Analyse) part pattern analysis: 1) & phi; 50mm & times; 770mm self-roundness tolerance is 0.005mm. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. 2) Left end M39 & times; 2-6g thread and piston rod & phi; 50mm center line coaxial tolerance is & phi; 0.05mm. 3)

The 1:20 conical surface has a circular runout tolerance of 0.005 mm. 5)

1:20 conical surface color inspection, contact area is not less than 80%. 6) & phi; 50mm & times; 770mm surface nitriding (chemical heat treatment process infiltrated into the surface of the workpiece), nitriding layer depth 0.2 ~ 0.3mm, surface hardness (Hardness) 62 ~ 65HRC. The material 38CrMoALA is a commonly used steel for nitriding treatment. Piston rod machining process card cylinder piston rod processing process card and process analysis (Analyse) process analysis: 1) piston rod in normal use, subjected to alternating load, φ 50mm & times; 770mm with sealing device reciprocating friction Surface, so it requires high hardness and wear resistance. The piston rod adopts 38CrMoALA material, φ 50mm× 770mm part after quenching and tempering and surface nitriding, the core hardness is 28~32HRC, the surface nitriding layer depth is 0.2~0.3mm, and the surface hardness is 62~65HRC. In this way, the piston rod has both a certain toughness and a good wear resistance. 2) The piston rod structure is relatively simple, but the length to diameter ratio is very large. It belongs to the elongated shaft type parts and has poor rigidity. In order to ensure the machining accuracy (accuracy), the roughing and the fine grinding are separated during turning, and the rough and fine are The car is always used with the tool holder to reduce the deformation of the workpiece during machining. The center frame is used when machining the threads at both ends. 3) When selecting the (xuanze) positioning reference, in order to ensure the coaxiality tolerance of the parts and the mutual positional accuracy of each part, all the machining steps are positioned by two center holes, which conforms to the principle of standardization. 4) When the outer surface is ground, the workpiece is easy to produce a knife and elastic deformation, which affects the accuracy of the piston rod. Therefore, the center hole should be repaired during processing, and the center hole should be cleaned, the tightness between the center hole and the tip should be appropriate, and good lubrication should be ensured. Grinding wheel is generally selected: abrasive white corundum (WA), particle size 60#, soft or medium or ceramic bond in hardness, and the width of the grinding wheel should be narrower to reduce the radial grinding force, attention to the amount of grinding during processing. The choice, especially the depth of grinding, is small. 5) in grinding & phi; 50mm & times; 770mm outer circle and

At 1:20 taper, the two processes must be performed separately. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. Grinding

When the 1:20 taper is used, the test piece must be ground first, and the test piece must be qualified before the workpiece can be formally ground.

1:20 conical surface inspection, using standard

1:20 ring color inspection, the contact surface should be no less than 80%. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. 6) In order to ensure the stability (precision: stable stability; no change) of the piston (pston) rod processing accuracy (manual adjustment), manual alignment is not allowed in the whole process of machining (guò ché ng). 7) When nitriding (chemical heat treatment process that penetrates the surface of the workpiece), the threaded part and the like should be protected by a protective device.

The piston ring elasticity of the piston rod can be divided into several types.

You may also be interested in this

Related Reading