your current location:Home>Concentration and dispersion of piston rod processing

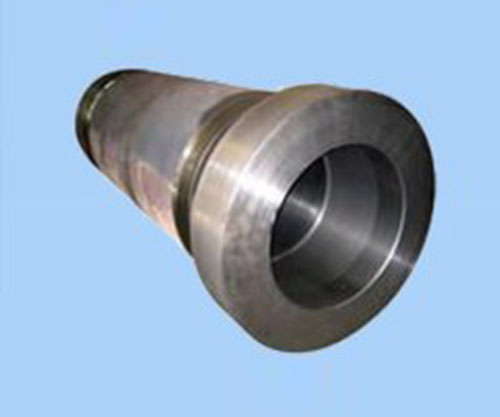

Concentration and dispersion of piston rod processing

Published: 201905-11 Clicks: times

The processing quality of the piston rod is relatively high. The surface roughness (cū cāo) requires a maximum of Ra 0.4 & mu; m, and several other round jumps also have higher position accuracy (accuracy) requirements. The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. The hollow piston rod refers to a hollow piston rod having an annular cross section. The finishing plan (fāng à n) determines the machining of the piston rod into five stages: roughing (rough outer circle, end face and drilling center hole, etc.), finishing car (external round, Steps and secondary surfaces, etc.), rough grinding (rough grinding of the outer circle), semi-finishing, fine grinding. The type of production of the piston rod is batch production. The structural complexity of the parts is general, but there are high technical requirements. The process of the shaft can be arranged by the principle of process concentration. Special machine tools and some high-productivity special equipment (shè bèi), with special fixtures and partial scribing to achieve precision (accuracy) to minimize the number of processes, shorten the process and increase production Efficiency. The principle of process concentration is adopted to ensure the positional accuracy requirement between each processing surface, save the time for installing the workpiece, reduce the number of workpiece movements, simplify the production planning, production organization, and reduce the number of work clamping. The auxiliary time is shortened. The production program of the piston rod is produced in batches, so the special clamps for the three-clamp chuck, the double-tip and the milling machine are used. The principle of determining the amount of cutting: First, choose the amount of backing knife as much as possible, and secondly, under the condition that the machine power and stiffness allow, and the condition of processing surface roughness (Condition), select as much as possible. Large feed rate. Finally, the optimum cutting speed is determined according to the formula. Want to know more about piston rods, cylinder rods, piston rod cylinders, mechanical guide columns, precision optical axes, and extra long piston rods.

You may also be interested in this

Related Reading