your current location:Home>What is the seal between the piston rod and the cylinder?

What is the seal between the piston rod and the cylinder?

Published: 201905-11 Clicks: times

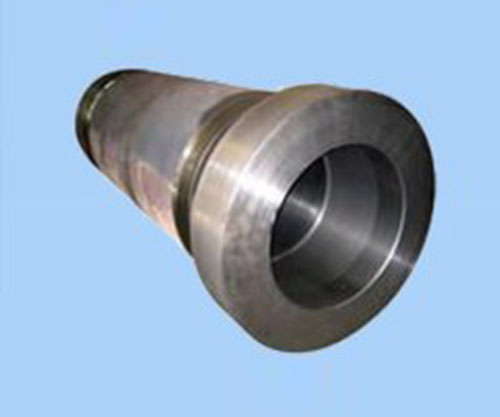

It is well known that the gap between the piston rod and the cylinder (compressed air) is well sealed. The piston rod is a connecting member for supporting the piston to perform work in the cylinder (compressed air) motion executing component. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. The hollow piston rod refers to a hollow piston rod having an annular cross section. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. However, in the process of using the piston rod (guò ché ng), the cylinder (compressed air) has a gap, so we must seal the gap. So what is the seal between the piston rod and the cylinder (compressed air)? In the case of the Condition, the seal between the piston rod and the cylinder (compressed air) is mainly sealed with a packing. Packing seal is a dynamic seal used in the moving parts of process machines and equipment (shè bè i), mainly used in the mechanical industry, such as plungers or piston rods of compressors and linear and spiral motion valves (function: cut-off, The seal between the stem and the fixed body of the diversion, regulation, shunt, etc.). The packing seal of the piston rod is mainly obtained by means of the gas pressure difference before and after the sealing to obtain a self-tightening seal. The clearance in the piston rod packing ring generally has the following clearance: the slit clearance: mainly used to compensate for the wear of the packing ring (a basic type of component failure). Axial clearance: It is mainly used to ensure that the packing ring can float freely, otherwise the piston rod can't work normally. Radial clearance: Avoid the sinking of the piston rod, so that the packing ring is pressed to avoid deformation or damage. According to the contents of the above website (tōng guò), it can be seen that the gap between the piston rod and the cylinder (compressed air) is sealed by a packing. However, when the packing is sealed, different packing sealing structures are selected according to the actual pressure of the gas before and after the sealing, the nature of the gas, and the requirements for the sealing.

You may also be interested in this

Related Reading