your current location:Home>Cylinder piston rod for maintenance techniques

Cylinder piston rod for maintenance techniques

Published: 201905-11 Clicks: times

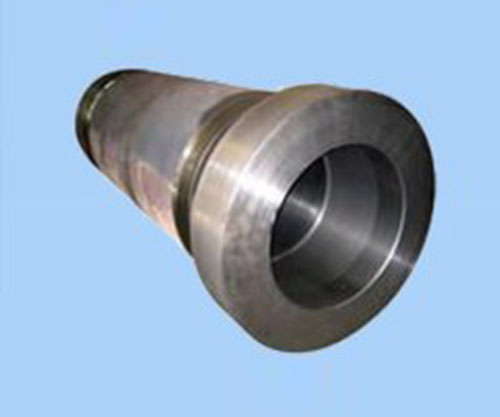

1, the car has an outer diameter (outer diameter) 185m

M, 150mm long cylinder when the mold, sawing along the axis, one for the rough mold, the other for the fine mold. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. The hollow piston rod refers to a hollow piston rod having an annular cross section. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. 2. Clean the parts to be welded first, then use the wet mud to keep the traces around. 3. Select a welding rod with a diameter of 2.5mm, adjust the current of the welding machine to 120A, and adopt a straight line method to smoothly weld. 4. After all the welding is completed, the mud and slag are removed, and the rough boring is carried out along the circumference of the piston rod and the machining allowance of 0.1-0.2 mm is left. 5. Reuse the 320-gauge sand 蘸 (zhà n) kerosene with a precision mold to grind the cylinder (compressed air) piston rod to the specified (guī dì ng) size. 6. Finally, carry out manual polishing with kerosene (zhà n) kerosene on the back of the cloth. After measurement, the maximum deviation is only 0.03mm. After the crane was repaired, after a year and a half of use, the hydraulic cylinder never showed any leakage, and the piston rod was smooth and rust-free. 7. Apply a thin layer of red ink on the inner wall of the rough mold, then press the rough mold against the axis of the piston rod to be repaired several times along the axis, and then use the fine boring to make the cylinder piston rod heavier red. Printed off. This is repeated repairs, leaving a machining allowance of 0.04-0.07mm. Want to know more about piston rods, cylinder rods, piston rod cylinders, mechanical guide columns, precision optical axes, and long piston rods. Stay tuned for Wuxi (xī) City Yushen Hydraulic Machinery Co., Ltd. (Company) official website

You may also be interested in this

Related Reading