your current location:Home>How to solve the wear of the hydraulic cylinder piston rod?

How to solve the wear of the hydraulic cylinder piston rod?

Published: 201905-11 Clicks: times

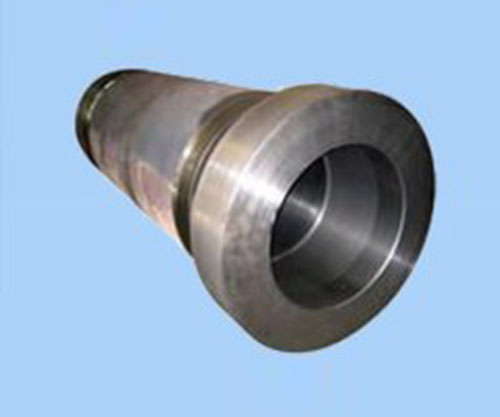

As we all know, the energy of the hydraulic brick machine comes from the hydraulic cylinder. The hydraulic system transmits the hydraulic energy to the hydraulic cylinder and pushes the hydraulic cylinder to press and mold the mixed raw materials. The performance and quality of the hydraulic cylinder directly determines the performance of the equipment. Hydraulic cylinders often have problems such as no pressure on the hydraulic cylinder, serious wear on the hydraulic piston rod, and oil leakage from the hydraulic cylinder. Today, follow the professional manufacturer of hydraulic piston rods to learn about the causes of the hydraulic cylinder piston rod wear and the corresponding solutions. .

In the initial stage of operation, the piston rod of the hydraulic cylinder often wears badly. During the pressing and lifting of the piston rod, strip grooves appear and are uneven. For users who don't understand, there is nothing, as long as they can work, and for users and technicians with certain basic knowledge, they should immediately stop the inspection and promptly give them a solution, otherwise the cylinder will be scrapped. If the pulling time is long, the piston rod is seriously worn, the opening gap and the side gap are increased, the elastic force is weakened, the tightness is lowered, and oil leakage and pressure are small.

So how do I resolve the wear and tear of hydraulic piston rods?

Now that we know the cause of the piston rod wear in the hydraulic cylinder, we know how to solve the problem. Let's briefly explain the solution:

1. For the serious wear-free and irreparable value, you can directly replace the new cylinder. After replacing it, you should observe whether the problem will reappear;

2. If it is caused by dirty oil, replace the oil, clean the hydraulic system and put in clean oil;

3. Due to oil seal problems, high quality oil seals should be replaced;

4. If the column and nut of the equipment should be increased due to the imbalance of force, make the basic balance in four directions;

5. If the hydraulic cylinder processing accuracy is caused, it is recommended to replace the supplier.

Hydraulic cylinders on hydraulic brick machines are equipment with high accuracy requirements. Pay more attention to whether there are any abnormalities during their work, and always maintain them properly.

You may also be interested in this

Related Reading