your current location:Home>There are several requirements for the production of piston

There are several requirements for the production of piston

Published: 201905-11 Clicks: times

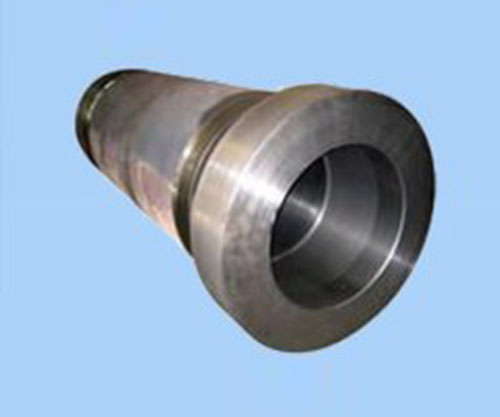

Piston rods in the work and production requirements according to different conditions (Condition) need to go through different processing techniques, quenching and plating methods are two very important ways in the production of piston rods.

Quenching and tempering can help to seal the tiny cracks on the piston surface of the piston and improve the resistance to corrosion and erosion. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. Simple plating improves surface wear resistance and the piston rod slows down wear during use.

There is also a surface nitriding (chemical heat treatment process that penetrates the surface of the workpiece) to improve the hardness of the piston rod at one time, which is often used in combination with a single-column hydraulic machine to achieve the overall hardness of the surface. . The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. Through (tōng guò) quenching and tempering, nitriding to improve hardness and surface state, plating to improve the surface wear resistance is excellent performance of the piston rod.

and its processing technology can improve the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thus improving the fatigue strength of the cylinder rod. The hollow piston rod refers to a hollow piston rod having an annular cross section. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. Through roll forming, the rolling surface forms a cold hardening layer, which minimizes the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding grinding caused by grinding. Burns. After rolling, the surface roughness value is reduced to improve the compounding property. At the same time, the friction damage to the seal ring or the seal during the movement of the cylinder rod piston is reduced, and the overall use time of the cylinder is improved. The rolling process is an efficient (referred to as high performance) high quality process measure (pointer to solution to the problem).

You may also be interested in this

Related Reading