your current location:Home>Cause Analysis and Improvement Measures for Leakage of Cylin

Cause Analysis and Improvement Measures for Leakage of Cylin

Published: 201905-11 Clicks: times

Analysis of the causes of leakage outside the piston rod of the cylinder and improvement measures

Hydraulic cylinders are important actuators for engineering machinery. The stability of their quality directly affects the efficiency and reliability of construction machinery (an important part of the equipment industry). Through (tōng guò) statistical analysis of the three-package failure rate of the loader, the hydraulic cylinder problem ranks fourth, and the leakage of the piston rod of the hydraulic cylinder is the most prominent quality problem. Although various hydraulic cylinder production companies have taken various measures (pointers to solve the problem) to improve, the effect is not very significant. Through the main reasons for the early leakage of the piston rod, the corresponding improvement measures are proposed.

1. Analysis of the causes of piston rod leakage in the early stage of hydraulic cylinder

The conventional opinion is that the main cause of leakage of the piston rod outside the piston rod is the failure of the seal ring and oil contamination. Through the dismantling of the hydraulic cylinders that have been returned due to the leakage of the piston rods in the market, it is found that the seal rings have different degrees of wear, scratches, aging, etc. From the actual detection of the failure of the hydraulic cylinder seals, the main reasons are as follows: Br /> (1) The dustproof ring has poor dustproof effect.

In actual use, people pay insufficient attention to the dust-proof effect of the hydraulic cylinder dust-proof ring, which is reflected in the following two aspects:

1 The selection of the dust ring structure is unreasonable. As shown in Figure 1, with the multi-purpose application of construction machinery, especially for individual users in high-pollution coal mines, mines, etc., continually continually over ten hours of overloading and over-temperature use, the dust-proof ring must be required. It has high anti-pollution and high temperature resistance. At present, the single lip dust ring can no longer meet the needs of construction machinery. From the perspective of the hydraulic cylinder dust ring for dismantling, the dust protection function is basically lost, so that the pollutants enter from the piston rod, causing the seal wear failure.

2 The dust-proof ring has poor protection measures during assembly. Mainly manifested in the painting process of construction machinery and machinery, no protective measures are taken for the hydraulic cylinder dust ring, resulting in residual paint on the lip of the dust ring, which has a certain vandalism effect on the dust ring, affecting dust prevention. effect. This can be illustrated by the presence of paint inside the dust ring from the hydraulic cylinder that was removed.

(2) The combined seal structure for the shaft is unreasonable.

At present, the main sealing structure of the piston rod is dust ring + low pressure seal (Y-ring) + high pressure seal (combination seal for shaft). After years of research, the Y-ring is a relatively mature structure, plus the application of imported Y-rings. There is basically no problem with the low pressure seal quality. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. The price of the composite sealing member for the shaft is relatively high, and the design angle of the sealing lip of the domestic component is unreasonable, which easily causes the material flow problem in the high temperature state of the lip, which causes the size and shape of the sealing lip to change, resulting in failure of the sealing performance. The pressure is concentrated at the low-pressure seal Y-ring, so that the early piston rod leakage problem occurs. From the hydraulic cylinders that were dismantled, the above problems were found to exist.

(3) The surface of the piston rod is bumped.

During the lifting process, due to the movement of the bucket, the material in the bucket slides down and squats on the surface of the protruding piston rod, causing tiny pits on the surface of the piston rod, increasing the friction between the sealing ring and the piston rod. , the seal ring wear failure. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. At present, this has become one of the main problems (Emerson) of the early piston rod leakage of hydraulic cylinders.

(4) The matching clearance between the piston rod and the guide sleeve is unreasonable.

According to the hydraulic cylinder design principle, the fitting tolerance of the piston rod and the guide sleeve is H9/f8. However, in practical applications, if the two are matched to the minimum tolerance value, due to the long-term overloading of the construction machinery (an important part of the equipment industry), the material expansion under the condition of the high temperature condition may easily cause the oil film on the surface of the piston rod. Sharply reduced, the lubrication effect of the sealing lip is reduced, and the local temperature exceeds the allowable temperature of the sealing ring, so that the sealing ring is aging at a high temperature and the sealing effect is lost. The market user feedback blackening problem on the surface of the piston rod is caused by the above reasons.

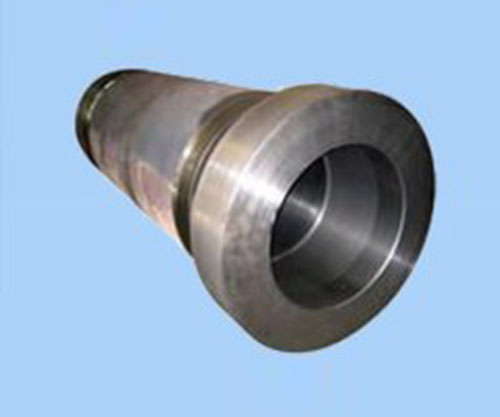

From the investigation and analysis of the causes of the leakage of the piston rod outside the hydraulic cylinder for several years, the above problems are the main causes of the piston rod leakage in the early stage of the hydraulic cylinder, and the proportion is over 60%. The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts.

2. Main measures to reduce the leakage of piston rods in the early stage of hydraulic cylinders

(1) Select the inner and outer double lip dust ring. The structure is shown in Figure 2, so that the dust ring acts to prevent dirt from entering the hydraulic cylinder from the lip and the bottom of the groove.

(2) Add protective measures to the dust-proof ring in the hydraulic cylinder and the whole painting process (guò ché ng). Learning from the experience of foreign hydraulic cylinder dust-proof protection, a special sealing ring should be installed at the lip of the dust-proof ring to effectively isolate the paint from the dust-proof ring. After the painting is completed, the special sealing ring is removed.

(3) Improve the combined seal structure for the shaft. As shown in Fig. 3, the R1 arc transition and the sealing lip are increased by 7° at the edge of the combined seal edge of the shaft to avoid the flow problem at the sealing lip and the edge material at high temperatures. Through the improvement of (tōng guò), even if the flow of the lip material occurs, the sealing effect of the combined seal is not reduced due to the material flow space.

(4) The intermediate rod of the piston rod is quenched. Through medium frequency quenching, the hardness of the piston rod base body can be increased, which can increase the anti-collision capability of the piston rod surface and reduce the surface roughness of the piston rod. In addition, it is also believed that the existence of a hardened layer with a depth of 2 mm or more makes the entire piston rod form a cylindrical structure, which can improve the bending strength of the piston rod.

(5) Take the protection measures of the piston rod surface. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. With the deep understanding of the problem of hydraulic cylinder piston rod bumping in the construction machinery, the loader production plant has started to have a serious impact on the piston rod hydraulic cylinder, in the piston rod earrings ; Add a protective plate to effectively reduce and avoid the hidden danger of the piston rod.

(6) Reasonably design and match the matching clearance between the piston rod and the guide sleeve. Under the premise of ensuring the safety clearance of the sealing ring, the supporting ring should have sufficient oil film thickness through the support ring to ensure the lubrication of the sealing lip and avoid abnormal high temperature due to friction.

You may also be interested in this

Related Reading