your current location:Home>How to meet the requirements of producing stainless steel pi

How to meet the requirements of producing stainless steel pi

Published: 201905-11 Clicks: times

In fact, many of our friends around us are using stainless steel (stainless acid-resistant steel) piston rods, of course, we should understand when we use his specific work There are more black markets for (Find out) and mastering (knowing and using). Therefore, we also specifically learned some information in this regard, hoping to help everyone's homework. Let's take a look at the detailed content below.

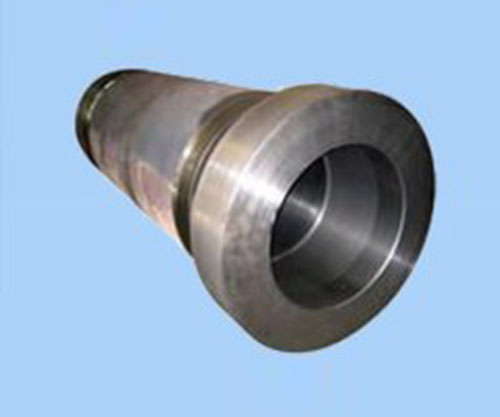

When we produce (Produce) stainless steel (stainless acid-resistant steel) piston rod, we can use the method of quenching or plating or electroplating. In fact, these two methods are relatively simple. We only need to prevent him from having some faults, such as cracks or wear (a basic type of component failure) (Emerson). The piston rod of the cylinder has a piston rod at one end, and the air supply from the side of the piston generates air pressure, and the air pressure pushes the piston to generate a thrust and returns by the spring or the self weight. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements. After quenching and tempering, it can effectively improve the corrosion resistance, so it is better for stainless steel piston rods. Electroplating can also slow down his wear, so many friends prefer to use these two methods. If you are interested, you can also try it and see how his effect works.

2, performance treatment of stainless steel (stainless steel) piston (piston) rod

In fact, when we use stainless steel (stainless acid-resistant steel) piston (piston) rod to work, we will use a lot of methods, of course, we also hope that his performance can be Improved. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. So we should find a way to see how it can improve his corrosion resistance, so that it can effectively reduce his fatigue, which is helpful for our homework. In addition, we should also look at the roughness of the surface of the stainless steel piston rod, we can also roll him, this method uses more friends, you can go to test (TestMeasure) Let's see which method works better.

In fact, no matter what kind of operation control we want to use stainless steel (stainless steel) piston (piston) rod, we should ensure that his function is complete. On this basis, we can carry out the follow-up operations. I believe everyone should understand it. If there are any questions from friends, you can ask them.

You may also be interested in this

Related Reading