your current location:Home>What do you think is better to check the piston rod?

What do you think is better to check the piston rod?

Published: 201905-11 Clicks: times

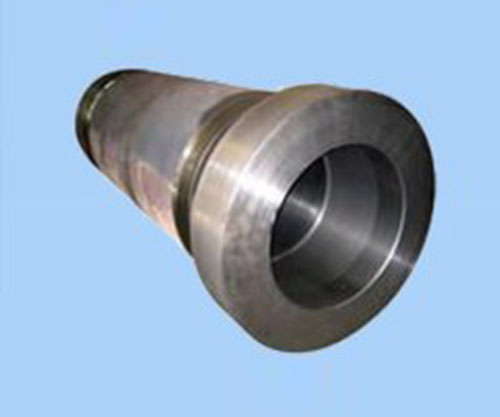

In fact, no matter what equipment we use (shè bè i) we should all do a good job of checking him. The hollow piston rod refers to a hollow piston rod having an annular cross section. So how do we check the piston rod? I hope that through the (tōng guò) our following introduction can help you. If you have any comments you would like to post after reading our introduction, you can tell us.

1, piston rod inspection procedure (procedure)

When we inspect the piston rod, it is usually after we finish processing, and then stop the experiment on water pressure (specifically: pressure) to see how his working pressure is. Of course, there can be no seepage or deformation in this process. If there is a crack in our piston rod, then it should generally be scrapped. If he has some friction and wear (a basic type of component failure), then we can try to find a way to repair it. According to different situations, the response we have made is different. I hope everyone can understand this.

2, Piston rod wear (a basic type of component failure) Condition (Condition)

No matter what device you are using, it takes a long time or a process in the process (guò chéng) to wear out (a basic type of component failure). It is normal, but for this The strength of wear is what we should control, otherwise we may not be able to handle and complete the work well. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The hydraulic piston rod cylinder, the piston rod (cylinder rod), the piston and the end cover are composed of several parts. In addition to this, you should also look at his accuracy (accuracy) after repair welding. For the different wear conditions of the piston rod, we should pay attention to it. If there is any problem that is not handled well (Emerson), we should also ask if there are any better suggestions from other friends. But no matter what, I hope everyone can pay attention to this issue.

The performance and quality of the piston rod we usually use are all we should guarantee. If you have your own ideas and opinions in this regard, you can say it and see what the specific form changes are. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. The hydraulic piston rod improves the surface corrosion resistance and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder rod. If it is useful to get our place, though open.

You may also be interested in this

Related Reading