your current location:Home>What is the cylinder piston rod

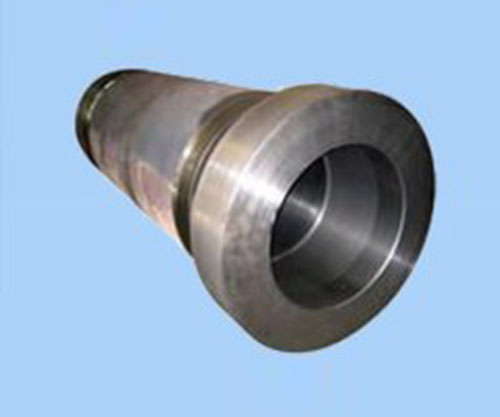

What is the cylinder piston rod

Published: 201905-11 Clicks: times

The piston rod of the cylinder is rolled, which has a surface residual compressive stress on the surface layer, which helps the sealing of the surface micro crack and hinders the expansion of the erosion. The cylinder piston rod wear ring can improve the guiding of the cylinder, reduce the wear of the piston seal and reduce the frictional resistance. Thereby, the surface is resistant to corrosion and corrosion, and the occurrence or expansion of fatigue cracks can be delayed, thereby improving the fatigue strength of the cylinder rod. Through roll forming, the rolling surface forms a cold hardening layer, which minimizes the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding grinding caused by grinding. Burns. After rolling, the reduction of the surface roughness (cū cāo) value can improve the compounding property. At the same time, the friction damage to the seal ring or the seal during the movement of the cylinder rod piston is reduced, and the overall use time of the cylinder is improved.

Rolling Technology Processing Principle: It is a kind of pressure finishing process, which utilizes the cold plasticity of metal at normal temperature and uses a rolling tool to apply a certain amount to the surface of the workpiece. The pressure causes the surface metal of the workpiece to flow plastically and fills into the original low-concave valleys of the original, and the surface roughness of the workpiece is reduced. When the hollow piston rods have the same material and the cross-sectional area is equal, the hollow piston rod has stronger torsion resistance and can withstand large external moments. The 45# piston rod connects the piston and the crosshead to transmit the force acting on the piston and drive the piston to move. Want to know more about cylinder piston rods, piston rod cylinders, mechanical guide columns, precision optical axes, and extra long piston rods.

. The 45# piston rod supports the connecting parts of the piston work. Most of them are used in the cylinder and cylinder movement executing parts. It is a moving part with frequent movement and high technical requirements.

You may also be interested in this

Related Reading