your current location:Home>Piston rod processing technology

Piston rod processing technology

Published: 201905-11 Clicks: times

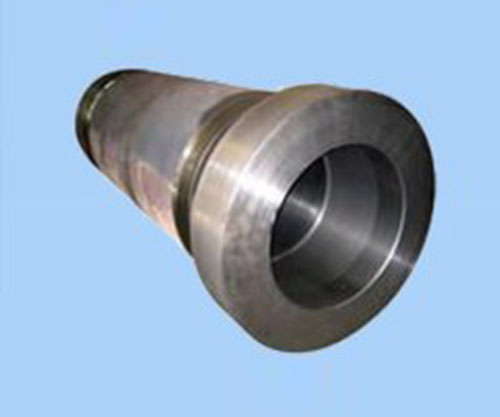

The piston rod is processed by rolling, and the residual stress on the surface layer is left to help the surface of the surface crack, which hinders the expansion of the erosion. Thereby, the surface corrosion resistance is improved, and the piston rod can delay the generation or expansion of the fatigue crack, thereby improving the fatigue strength of the cylinder rod. By rolling forming, the rolling surface forms a cold hardening layer, which reduces the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced to improve the compounding property. At the same time, the friction damage to the sealing ring or the sealing member during the movement of the cylinder rod piston is reduced, and the overall service life of the oil cylinder is improved. The rolling process is a high-efficiency and high-quality process. The 160mm diameter doctor's cutting roller indenter (45 steel seamless steel pipe) is used as an example to show the rolling effect. After rolling, the surface roughness of the cylinder rod is reduced from Ra3.2 to 6.3um before the rolling of the building to Ra0.4 to 0.8um, the surface hardness of the cylinder rod is increased by about 30%, and the fatigue strength of the cylinder rod surface is increased by 25%. The service life of the cylinder is increased by 2 to 3 times, and the rolling process is improved by about 15 times compared with the grinding process. The above data shows that the rolling process is highly efficient and can greatly improve the surface quality of the cylinder rod.

Specializing in the production of precision piston rods, it is manufactured with advanced technology of precision cold drawing, fine grinding and high precision polishing. All technical indicators meet and exceed national standards. It can be directly used in cylinders, cylinders, shock absorbers and piston rods, and is widely used in hydraulic and pneumatic, textile printing and dyeing, printing machinery guide rails, die casting machines, injection molding machine guide rods, ejector pins and four-column hydraulic press guide columns; fax machines, copiers, Some high-speed mimeographs, printers and other modern office machinery guide shafts and other industries and products with precision and slender shafts.

You may also be interested in this

Related Reading